01

- Acceptance inspection of raw materials

- SNUCONE imports titanium materials guaranteed of safety compliant with international standards, and professional inspectors of SNUCONE fully inspect imported titanium to accept such materials satisfying the requirements of inspection

02

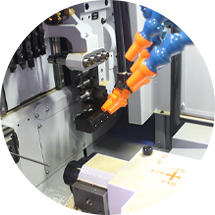

- CNC machining

- CNC machining engineers with rich skilled experiences process accepted titanium materials to produce correct and precise implants.

03

- Cleaning after machining

- Inside and outside of implant are cleaned with ultrasonic wave and steam off oily substances and foreign materials generated during CNC machining processes.

04

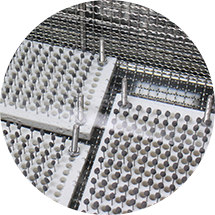

- Inspection of machining

- SNUCONE performs dimension inspection as well as other various in-house inspections to supply precise and safe products of high quality.

05

- Implants surface treatment

- Surface of implant is treated with authentic SLA technology of SNUCONE transferred from a German company.

06

- Cleaning after surface treatment

- Implants are removed of contaminants and foreign materials after surface treatment process, and then transferred to cleanroom

07

- Surface inspection

- The surface of implants is fully inspected for contamination or conditions in cleanroom free from contamination.

08

- Final cleaning in cleanroom

- Implants are finally cleaned in cleanroom to fully remove contaminants before packaging process.

09

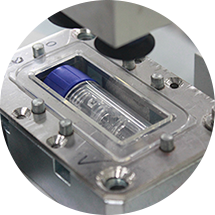

- Packaging in cleanroom

- Packaging process is performed in cleanroom for protecting implants from contamination.

10

- Gamma sterilization

- Gamma sterilization of strong penetration power sterilizes organic substances such as bacteria and molds, and yields no residual toxicity.

11

- Shipping inspection

- Packaging and labeling of finished products are inspected before shipping.